Precio FOB

Obtener el precio más reciente|

1 Piece Minimum Order

País:

China

N º de Modelo:

-

Precio FOB:

Lugar de origen:

zhuzhou city

Precio de pedido mínimo:

-

Cantidad de pedido mínimo:

1 Piece

Detalle de embalaje:

Caton

El tiempo de entrega:

15days

Capacidad de suministro:

-

Tipo de pago:

T/T, Western Union, Money Gram, PayPal, Other

Grupo de productos :

Persona de contacto å©·

Zhuzhou, Hunan

Dimensions:

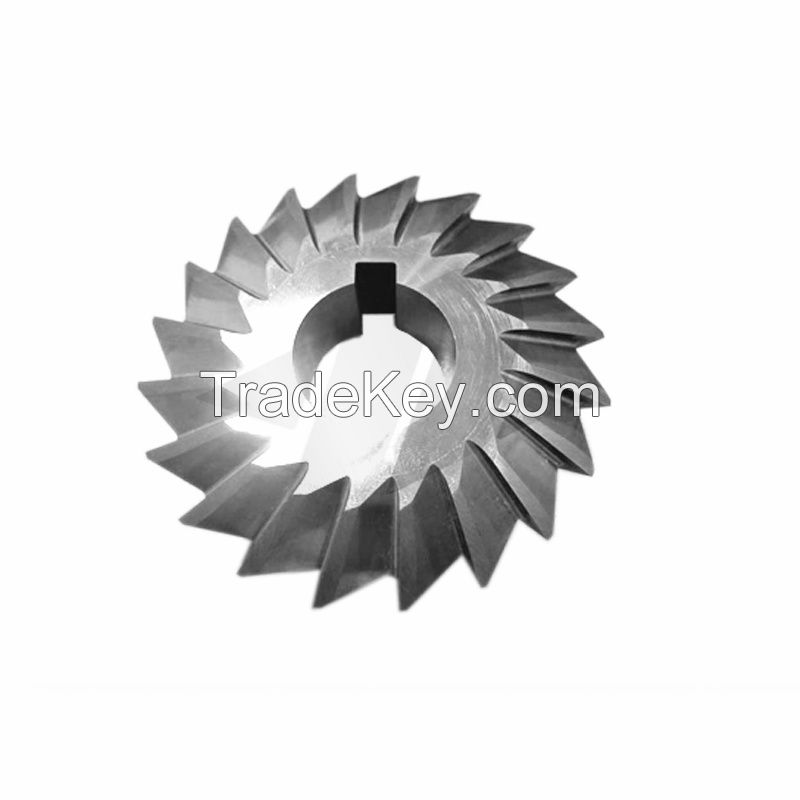

Outer diameter: φ *****0mm, aperture: φ ***0mm, thickness: 0.**7.0mm, tooth type: toothless, coarse tooth, middle tooth, fine tooth opening mode: milling, grinding, non grinding, full grinding tooth shape: sharp tooth, circular arc tooth, staggered tooth (left and right teeth, high and low teeth), R-shaped tooth, angle tooth, opposite tooth surface coating: natural color, various coatings. Material: hard alloy (tungsten steel K*0, K*5) forged high-performance high-speed steel M*2, W*8Cr4V (w*8), ***2 (M2), W9Mo3Cr4V (w9), etc

Product use:

It is mainly used for milling, trenching, sawing, cutting and blanking of ordinary steel, stainless steel, brass, aluminum alloy, plastic, titanium alloy, super hard cast iron, high nickel white copper, heat-resistant alloy, structural steel, alloy steel, cast steel, high manganese steel and other materials.

Special attention: receive non-standard customization, special customization. The picture is for reference only. According to the needs of customers, we can customize the different treatment of the required outer diameter, inner hole, thickness and number of teeth.

Precautions for use of carbide circular saw blade

| País: | China |

| N º de Modelo: | - |

| Precio FOB: | Obtener el precio más reciente |

| Lugar de origen: | zhuzhou city |

| Precio de pedido mínimo: | - |

| Cantidad de pedido mínimo: | 1 Piece |

| Detalle de embalaje: | Caton |

| El tiempo de entrega: | 15days |

| Capacidad de suministro: | - |

| Tipo de pago: | T/T, Western Union, Money Gram, PayPal, Other |

| Grupo de productos : | Carbide cutting tools |