Precio FOB

Obtener el precio más reciente500 ~ 2800 USD / Unit ( Negotiable )

|1 Unit Minimum Order

País:

China

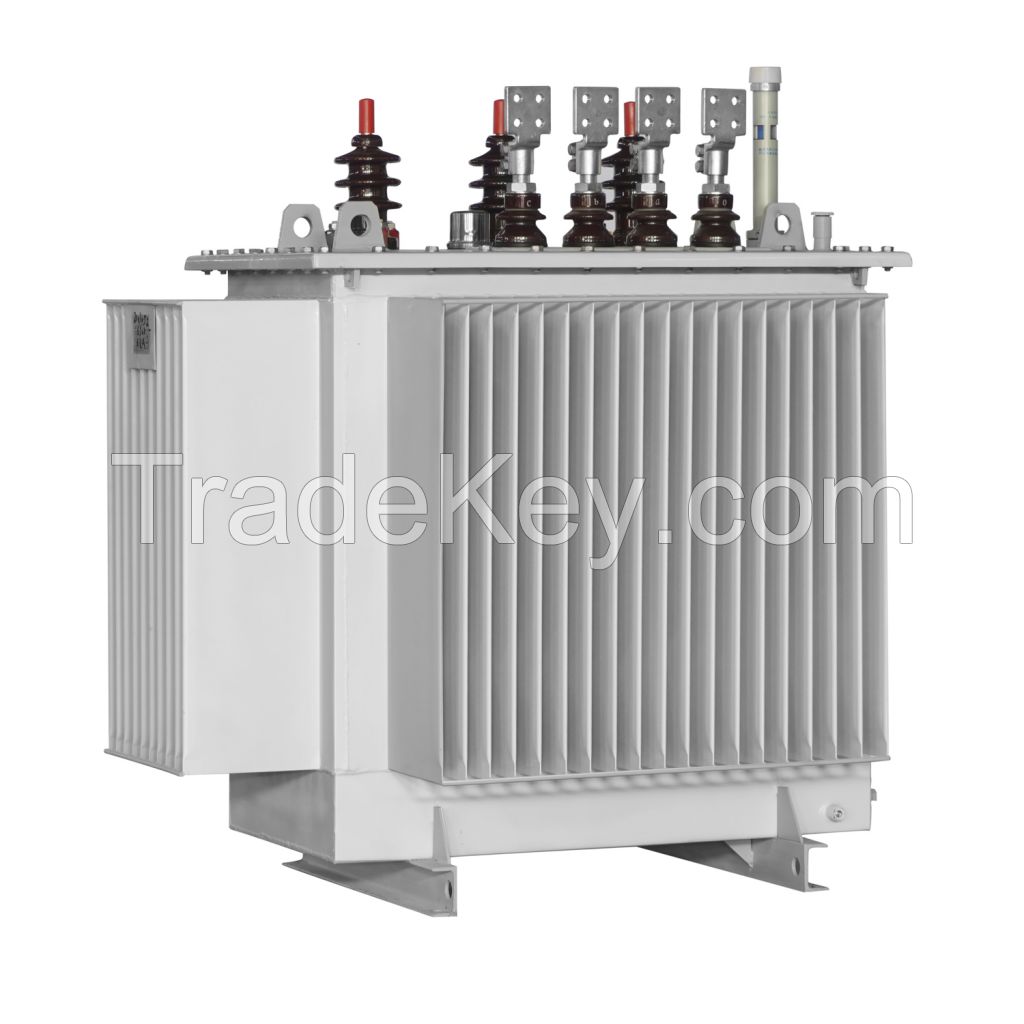

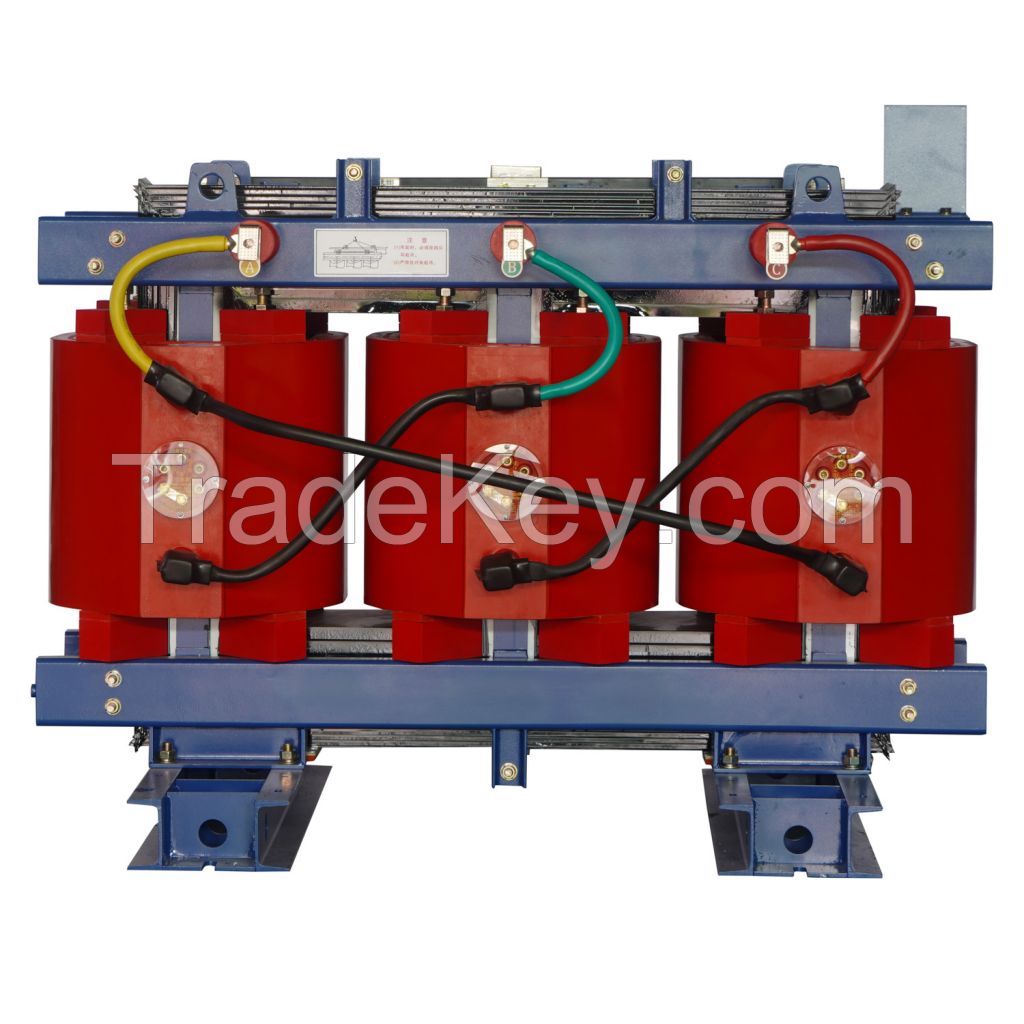

N º de Modelo:

S9, S10, S11, SCB

Precio FOB:

500 ~ 2800 USD / Unit ( Negotiable ) Obtener el precio más reciente

Lugar de origen:

guangdong ,china

Precio de pedido mínimo:

500 per Unit

Cantidad de pedido mínimo:

1 Unit

Detalle de embalaje:

wooden case

El tiempo de entrega:

15-20 days

Capacidad de suministro:

500 Unit per Month

Tipo de pago:

T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal

Grupo de productos :

Persona de contacto lirongxiao

Foshan, Guangdong

Product introduction

* The transformer core is made of imported

high-quality cold-rolled silicon steel sheet, which greatly reduces

no-load loss and no-load current. The core

is tightly bound to ensure the compactness and reduce

noise.

* The high and low voltage windings are made of

oxygen-free copper. The low voltage winding of **0KVA and below is

of double-layer cylinder structure, of **0kVA and above adopt double helix or four

helix structure. High-voltage winding adopts multi-layer cylinder

structure.

* Dyn*1 is used in the transformer connection group

to reduce the influence of harmonics on the power grid and improve

the quality of power supply.

* The transformer is a fully sealed structure, with

three coats of primer and one coat of finish paint applied on the

inner and outer surfaces. The product is salt fog proof,

moisture proof and fungus-proofing, beautiful, durable and

reliable

* The measured noise value is lower than the

standard and maintenance free under normal

operation.

| País: | China |

| N º de Modelo: | S9, S10, S11, SCB |

| Precio FOB: | 500 ~ 2800 / Unit ( Negotiable ) Obtener el precio más reciente |

| Lugar de origen: | guangdong ,china |

| Precio de pedido mínimo: | 500 per Unit |

| Cantidad de pedido mínimo: | 1 Unit |

| Detalle de embalaje: | wooden case |

| El tiempo de entrega: | 15-20 days |

| Capacidad de suministro: | 500 Unit per Month |

| Tipo de pago: | T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal |

| Grupo de productos : | transformer |